Tsanangudzo yeMeta: Ongorora epamusoro jekiseni ekuumba matekiniki emotokari headlight molds. Dzidza nezve kusarudzwa kwezvinhu, dhizaini chaiyo, uye mafambiro ekusimudzira mukugadzira marambi emota.

Nhanganyaya

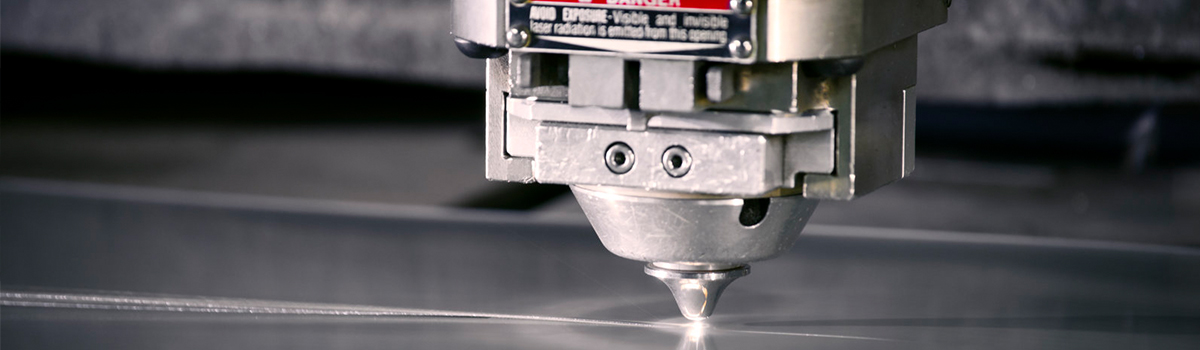

Indasitiri yekuvhenekesa yemotokari inoda kunyatsojeka, iine molds yemusoro inoda kushivirira pasi pe0.02mm. Sezvo dhizaini yemotokari inoshanduka ichienda kune yakaonda ma LED arrays uye inoshanduka yekutyaira matanda, jekiseni mold mainjiniya anotarisana nematambudziko asina kumboitika. Iri gwara rinotyora maitiro akakosha uye ekucheka-kumucheto mazano anotonga munda.

1. Kusarudzwa kwezvinhu: Kuenzanisa Optics & Durability

Target Keywords: polycarbonate jekiseni rekugadzira mwenje, mota-giredhi thermoplastics *

- PC (Polycarbonate): 90% yemwenje yemazuva ano inoshandisa PC kune yayo 89% chiedza kutapurirana uye 140 ° C kupisa kuramba.

- PMMA Lenzi: Sekondari lenzi dzinowanzobatanidza PMMA yekukwenya kuramba.

- Additives Matter: 0.3-0.5% UV stabilizers kudzivirira yellowing; anti-fog agents kuderedza mukati condensation.

Pro Tip: BASF's Lexan SLX uye Covestro's Makrolon AL inopa yakawedzera kuyerera kwemapombi emwenje akaomarara.

2. Core-Cavity Design: Kutarisana neThin-Wall Challenges

Target Keywords: dzakatetepa-madziro headlight mold dhizaini, mota dzemwenje yekutonhodza nzira *

- Rusvingo Ukobvu: 1.2-2.5mm madziro anoda high-speed jekiseni (800-1,200 mm/sec) kudzivirira kuzeza mavanga.

- Conformal Kutonhora: 3D-yakadhindwa yemhangura alloy chiteshi inovandudza kutonhora kwe40%, kuderedza kutenderera nguva.

- Surface Finishes: VDI 18-21 (textured) ye diffusers vs. SPI A1 (mirror) kune yakajeka lenses.

Nyaya Yekudzidza: Tesla Model 3 matrix LED module yakawana 0.005mm warpage uchishandisa gradient tembiricha kutonga.

3. Maitiro Parameters: Data-Driven Optimization

Target Keywords: majekiseni ekuumba maparamendi emarambi emota, mota yemwenje mold kusimbiswa *

| Parameter | Typical Range | Impact |

|——————————————————————————————|

| Melt Temp | 280-320°C (PC) | Optical kujeka |

| Jekiseni Pressure | 1,800-2,200 bar | Inozadza zvidiki |

| Packing Time | 8-12 seconds | Inodzivirira sink marks |

IoT Kubatanidzwa: Real-time pressure sensors inogadzirisa viscosity panguva yekuzadza (Industry 4.0 inoenderana).

4. Sustainability Trends Reshaping the Industry

Target Keywords: eco-inoshamwaridzika headlight molds, zvakadzokororwa zvinhu mumotokari mwenje *

-Kemikari Kudzokorodza: Eastman's PC yekuvandudza tekinoroji inobvumira makumi mashanu muzana zvakadzokororwa zvemukati pasina kutsvuka.

- Mold Coatings: CrN / AlCrN PVD coatings inowedzera hupenyu hwehuku ne300%, kuderedza tsvina yesimbi.

-Kuchengetedza Kwemagetsi: Ese-magetsi madhindindi anocheka kushandiswa kwesimba ne60% vs hydraulic system.

Regulatory Note: EU 2025 ELV Directive inorayira 95% headlight recyclability.

5. Emerging Technologies to Watch

Target Keywords: AI mukugadzira mold, 3D yakadhindwa mota molds *

- AI Simulation: Autodesk Moldflow 2024 inofanotaura weld mitsetse ine 92% chokwadi.

- Hybrid Tooling: Yakaomeswa inoisa (HRC 54-56) yakasanganiswa ne 3D yakadhindwa conformal kutonhora.

-Smart Molds: Yakamisikidzwa RFID tag inoteedzera nhoroondo yekugadzirisa uye kupfeka mapatani.

Mhedziso

Kugona kuumba mwenje wemotokari kunoda kubatanidza zvinhu zvesainzi, chaiyo engineering, uye hunyanzvi hwedhijitari. Sezvo mota dzinozvimiririra dzichityaira kudiwa kweakangwara masisitimu ekuvhenekesa, kutora aya epamberi nzira kunoisa vagadziri kumberi kweindasitiri.

Call to Action: Unoda kuongororwa kwe moldflow kune yako inotevera headlight project? [Bata nyanzvi dzedu] kuti uwane ruzivo rwemahara.

Nguva yekutumira: Kubvumbi-01-2025